DAVID L. ELLIS CO., INC.

HARDNESS & CALIBRATION SERVICES SINCE 1983

The Industry

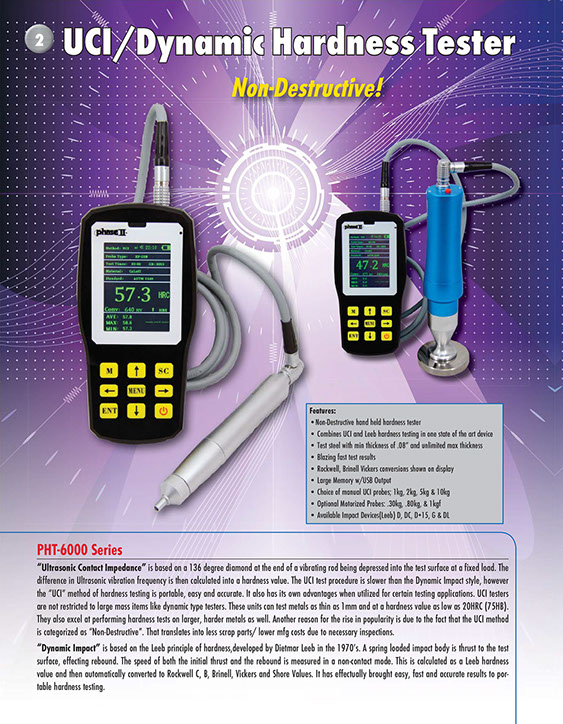

Do you have an Ultrasonic Hardness Tester and

having problems reading Rockwell, Vickers or Brinell?

We can help solve this problem with test blocks.

Give us a call. 1.978.897.1795

Do you use a Leeb’s Tester?

All testers come with a steel test block.

If you are checking aluminum you need an aluminum test block.

We have them.

Just call and tell us what scale you need (HRBW, Vickers, HRE, etc.) 1.978.897.1795

x

Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for over 250 years. Certainly, as a material property, its value and importance cannot be understated, the information from a hardness test can complement and often be used in conjunction with other material verification techniques such as tensile or compression to provide critical performance information. How important and useful is material and hardness testing? Consider the information provided and its significance in structural, aerospace, automotive, quality control, failure analysis and many other forms of manufacturing and industry. Determining these material properties provides valuable insight to the durability, strength, flexibility, and capabilities of a variety of component types from raw materials to prepared specimens, and finished goods. Over the years, various methods for determining the hardness of materials have been developed and employed at varying levels of success. From early forms of scratch testing to sophisticated automated imaging, hardness testing has evolved into an efficient, accurate, and valued material test method.

As the 20th century progressed and endured two world wars, with the simultaneous blossoming of the industrial revolution, increased manufacturing requirements and global industrialization brought an urgent demand for more refined and efficient test methods and new techniques began to develop. Accurate, efficient forms of testing were needed in reaction to heavy manufacturing demands, structural failures, and the need to design sufficient material integrity into the growing global infrastructure.

Today, hardness testing plays an important role in materials testing, quality control, and acceptance of components. We depend on the data to verify the heat treatment, structural integrity, and quality of components to determine if a material has the properties necessary for its intended use. Through the years, establishing means of increasingly more productive and effective testing through refining traditional testing design has given way to new cutting edge methods that perform and interpret hardness tests more effectively than ever before. Hardness tests very useful in industrial and R&D applications and in insuring that the materials utilized in the things we use every day contribute to a well-engineered, efficient, and safe world.

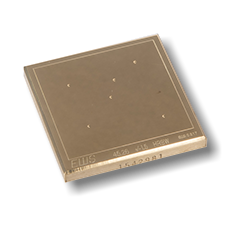

David Ellis Co, Inc. manufactures hardness test blocks developed by people who understand the standards & specifications that have to be met by manufacturers today. We have every possible scale and range of Brinell, and Rockwell blocks in stock, as well as Knoop, and Vickers Micro blocks, and heavy load Vickers blocks.

A full line of hardness testing accessories is available, including special adapters and other hard to find parts. Standard items are available through the Sales Desk: 800.472.6962, (US and Canada only) or click on the Order Form.

Brinell, Micro and Rockwell

Being a manufacturer of test blocks, we have the most hardness ranges in all scales available.

Our calibration engineers have over 125 years of combined experience. We service, repair and provide certificates for all makes and types of hardness testers to the applicable standards, i.e. ASTM, ISO and military specifications. We travel to your site or you can ship portable testers to us.

Richard Ellis, General Manager/Consultation

Richard J. Snow, Quality Control

Call with questions, leave with answers: 800-472-6962. (US and Canada only)

Our History

The David L. Ellis Co. was formed in 1946 by David L. Ellis. He was a high temperature metallurgy specialist. He represented various companies until his retirement in 1983.

Richard A. Ellis, David’s son, incorporated the company in 1983 after leaving Wilson Hardness Testing Instruments where he was a district manager for Eastern New England at the time.

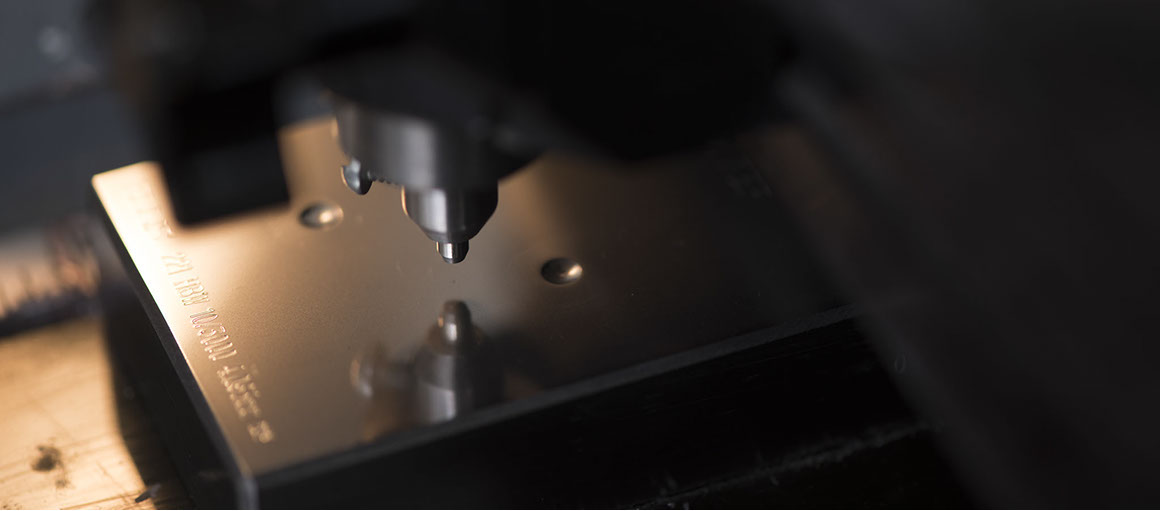

David L. Ellis Co., Inc. (DLECI) was selling and servicing accredited hardness testers. In 1986 the company manufactured its first Rockwell Hardness Test Block.

Now the company ships Rockwell, Brinell, Vickers, Knoop and LD blocks all over the world.

In early 2000 DLECI was NVLAP accredited and still is.

Today, DLECI is a accredited lab for hardness testing. If you have low volume and cannot justify the cost of high quality hardness testing equipment, then call us and we can measure your parts for you.

Accreditation

David L. Ellis Co, Inc. is accredited by NVLAP (Lab Code 200127).

Click on the links below to view our scope documentation*:

We offer the largest Hardness Test Block selection in the industry. If you don’t see what you're looking for - Ask! All of our Hardness Test Blocks come with Accreditation. All the blocks are calibrated and accredited to ISO guide 25 and will meet automotive and aerospace standards. The HRC test blocks are calibrated on the new NIST level.

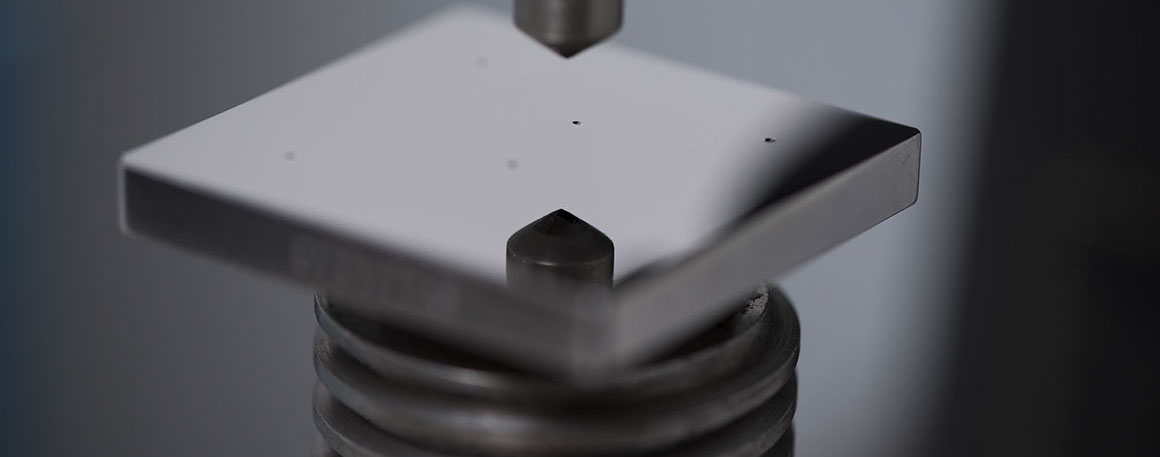

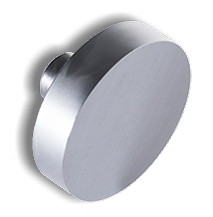

Anvils

Anvils help ensure accurate test results by supporting the test specimen during the application of the major load during a hardness test. Rockwell anvils are compatible with most Rockwell hardness testers.

Indentron® and Versitron® are registered trademarks of Newage Testing Instruments, Inc.

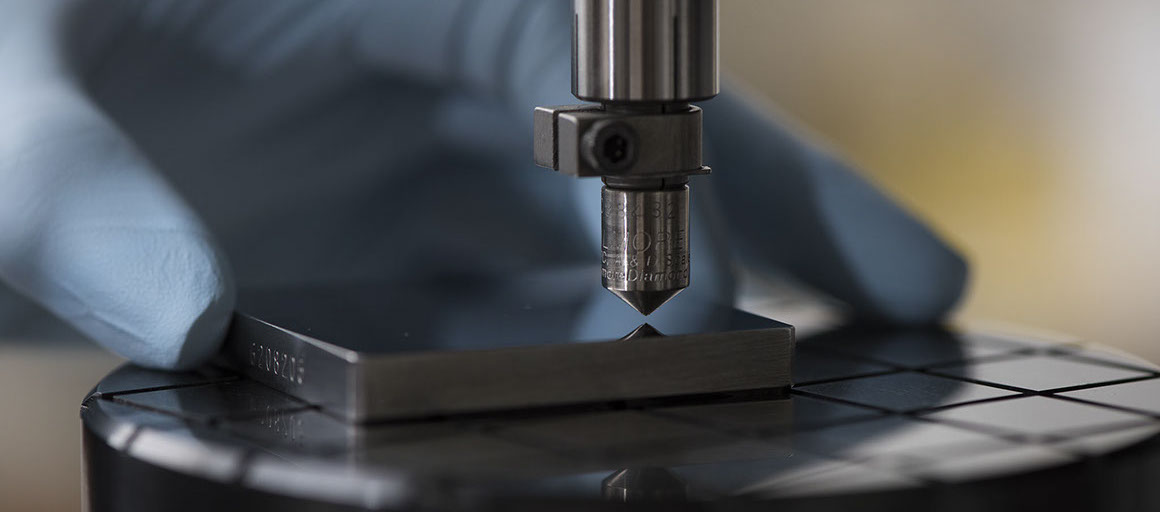

Each diamond penetrator is mounted in conformity with its grain structure, to assure balanced pressure and prevent early wear or breakage. They are precision ground, lapped and polished.

We also subject each diamond penetrator to a strict performance test before it is approved

and accredited for sale.

The David L. Ellis Co., Inc. is getting a lot of calls about Ultrasonic Hardness Testers. The problem is “How do you calibrate the tester?” The answer is “Special Material" Blocks. We can help you. Give us a call.

If you have a “Leebs” tester we can calibrate it for you. We recommend you have dual calibration on the blocks. Example: If you use HRC, get the block calibrated to HRC NIST and LD. If it is another scale (HRB Vickers, etc.) we can do dual calibration.

If you use Leebs, the standard blocks that come with the tester is HRC 58. If the tester is used to check HRC 25, HRBW AL, etc., you should get a block close to what you are testing. We have LD & LG blocks from HBW AL to HRC 58.

- David L Ellis Co., Inc.

Industry News

Direct Verification of Hardness Testers and Documentation

May 23, 2018, Acton, MA: By now some of you have heard rumors about testers failing direct verification and are not allowed to be used for qualifying parts or test items. This requirement can be found in ASTM E18-17e1 appendix A1. Please look at Table A1.1. It states that new testers must have direct verification. The basic issue is that old testers may not have ever had direct verification even when new, or there are no documents to prove it was ever done.

As a result now some accreditation bodies may require this direct information. If it cannot be shown, then direct verification can be attempted. At issue is whether the old tester meets ASTM E18-17e1 appendix A1. It is a near 100% certainty that the old testers will fail. Usually the forces and depth measurements are incorrect. In addition, it is virtually impossible to control the dwell times of the testing cycle as they are controlled by individuals.

Having said all that, it is an option to have the tester directly verified. It is a time consuming and an expensive undertaking. If it still fails, which it probably will, you will have spent a significant amount of money and still need to buy another tester that meets ASTM E18-17e1 appendix A1.

This requirement has existed since 2007, but it has not been enforced by auditors until recently.

- Robert Ellis, Quality Manager

Hardness – An Overview

April 25, 2018, Acton, MA: Hardness testing of metals, composites and minerals is the resistance to indentation, introduced by diamond or tungsten ball, and it is determined by measuring the permanent depth of the indentation. The hardness test is a fast and cost effective method for determining the condition of a material following heat treatment, ease of machining, or to provide insight into strength and wear resistance.

Rockwell, Brinell and Vickers/Knoop hardness testing is the most widely used method for determining the hardness of a material. Generally, the surface should be flat and sanded smooth to obtain an average of three of more readings.

The Brinell Hardness Test is utilized to measure hardness over a larger sample areas. Brinell hardness is particularly useful for castings and forgings that have a rough surface or micro structure too coarse for other hardness testing methods. The most common test in the USA is the Rockwell HRC for hard steel and HRBW for soft alloys. Thin metals are tested with Rockwell superficial scale. Brinell testing is often performed with a high test load (500 to 3000 kg most common in the USA) and a 10mm size indenter so the resulting indentation averages out most surface and sub-surface inconsistencies. The resulting impression is measured across at least two diameters and results averaged. The averaged diameter measurement is then converted to a Brinell hardness number. The lower loads with a 5, 2.5, and 1mm ball are very common in other parts of the world.

- David L Ellis Co., Inc.

Is hardness important in everyday life?

Yes, it is.

If you want to know how and why, rent and see CSI “Chasing The Bus” (Season 2, Episode 18, 2002). Sometimes hardness is a life or death situation!

http://www.cbs.com/shows/csi/video/jRN0Mk9ak7BB_Eq9RpYSjVH4aXI12rSz/csi-chasing-the-bus/

Product Sales Specials

David L. Ellis Co., Inc. is offering the following product

specials at deal pricing while supplies last:

1.) 4” x 4” x 3/4” Brinell Blocks now at same price as the 6” x 2 x 3/4” Blocks with dual certificates (ASTM & ISO). Call for hardness range and availability.

2.) New 6” x 41/2” x 3/4” available at special price. Grids and circle patterns available while

supplies last.

Over Stock

Brinell Blocks

1.) 4” x 4” 3,000kg, 10mm - Gray Finish Ranges - 192-216 HB - 281-291 HBW

2.) 4” x 4” 3,000kg, 10mm - Mirror Finish Ranges - 275 HBW - 372 HBW - 200 HBW

List Price Above: $180.00 each Accredited Special Price: $99.99 each Accredited

Limited quantity.

Calibration Services

We service and provide certificates for most Hardness Testers in the field. Portable Hardness Testers (Leebs, Shore, Rockwell, Brinell, Impressor, Ultrasonic) are calibrated in house. Recalibration and reconditioning of Brinell, Rockwell, Micro, Macro Leeds blocks are available

upon request.

Scroll down to view

Hardness Test Blocks

We offer the largest Hardness Test Block selection in the industry. If you don't see what you're looking for - Ask! All of our Hardness Test Blocks come with Accreditation. All the blocks are calibrated and accredited to ISO guide 25 and will meet automotive and aerospace standards. The HRC test blocks are calibrated on the new NIST level.

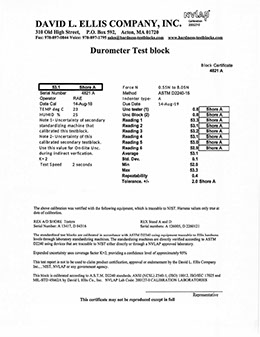

View a Sample Certificate

(click to view pdf below)

BRINELL

KNOOP

ROCKWELL

VICKERS

Our Best Selling Products

3.5 VEE

All Shank sizes are

0.75” (19.04 mm)

A1010

Pedestal Spot 1/4” Anvil

STEM - 1.0” (24 mm)

Flat - .25” (6.33 mm)

A1012

Pedestal Spot 1/2” Anvil

STEM - 1.0” (24 mm)

Flat - 0.5” (48 mm)

A1020

1.5” Flat Anvil

1.5” (38 mm)

A1023

1” Flat Anvil

1.0” (24 mm)

A1030

2 .5” Flat Anvil

2.5” (63 mm)

Standard Anvil 1.5” (38 mm)

A1040

Shallow “V” Anvil (shown)

Stem 1.0” (24mm)

1/4” N Anvil (58mm)

Brinell

6” x 2” x .75”

4” x 4” x .75”

6” x 4.5” x .75”

Diamond Penetrator

C, N, C&N

1/10” Ball Pen Unit

1/8” Ball Pen Unit

1/2” Ball Pen Unit

All Dimensions are Approximate

Calibration Kits

HRBW - 3 Blocks (H,M,L)

with accredited 1/16” Ball Pen Unit

HRFW - 3 Blocks (H,M,L)

with accredited 1/16” Ball Pen Unit

HREW - 3 Blocks (H,M,L) with accredited 1/16" Ball Pen Unit

HR15TW 3 Blocks (H,M,L) with accredited

HR30TW 1/16” Ball Pen Unit

HR45TW

HRC - 3 Blocks (H,M,L) with accredited “C” Diamond

HN15N - 3 Blocks (H,M,L) with accredited “N” diamond

HR3ON - 3 Blocks (H,M,L) with accredited “N” diamond

Other calibration kits by request

LG - 500 Range

Note:

A. For traceability HRC

or Brinell can be added

B. Dual calibration Block

available

Leebs Blocks

LD - 780 Range

680 Range

500 Range

LD - Aluminum Range

HB60 - 90

Vickers Blocks

Mircro Vickers (1kg or less)

Range 80 UVN to 2200 UHN

1.25” dia.

Heavy Load Vickers (1 kg to 50 kg)

2.0” Square (50 mm x 50 mm)

Range 80 UHN to 800

800 and up 1.25” dia. (32mm)

Knoop Blocks

Micro Knoop (1 kg or less)

Range 80 KHN to 700

1.25” dia.

Heavy Load Knoop

1 kg to 50 kg

Range 80 KHN to 700

2.0” Square

Rockwell Regular Hardness Test Block

Part No.

HRA

HRA

HRBW

HRC

HRD

HREW

HRFW

HRGW

HRGW

HRHW

HRKW

HRLW

HRMW

HRPW

HRRW

HRSW

HRVW

Penetrator

C Diamond

A Diamond (Carbide)

1/16” Ball

C Diamond

C Diamond

1/8” Ball

1/16” Ball

1/16” Ball

1/16” Ball

1/8” Ball

1/8” Ball

1/8” Ball

1/4” Ball

1/4” Ball

1/2” Ball

1/2” Ball

1/2” Ball

Load

60 Kg

60 Kg

100 Kg

150 Kg

100 Kg

100Kg

60 Kg

150 Kg

150Kg

60 Kg

150 Kg

60 Kg

100 Kg

150 Kg

60 Kg

100 Kg

150 Kg

Rockwell Superficial Hardness Test Block

Part No:

15N

30N

45N

15TW

30TW

45TW

15WW

30WW

45WW

15XW

30XW

45XW

15YW

30YW

45YW

Penetrator

N Diamond

N Diamond

N Diamond

1/16” Ball

1/16” Ball

1/16” Ball

1/8” Ball

1/8” Ball

1/8” Ball

1/4” Ball

1/4” Ball

1/4” Ball

1/2” Ball

1/2” Ball

1/2” Ball

Load

15 Kg

30 Kg

45 Kg

15 Kg

30 Kg

45 Kg

15 Kg

30Kg

45 Kg

15 Kg

30 Kg

45 Kg

15 Kg

30 Kg

45 Kg

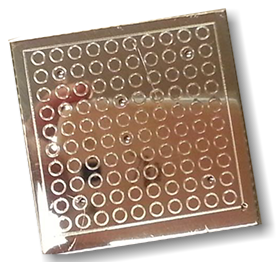

The David L. Ellis Co., Inc. offers

two types of gridded blocks for Rockwell test blocks

Circle Pattern

This design will solve the problem of distance between indents to meet the standard. Some customers complained that too much space was wasted. But this is the rule of ASTM E18-17e1.

Square Pattern

The block has a grid pattern on the whole block. The problem with the design is soft blocks make larger indents and won’t always meet ASTM E18-17e1 for distance between another indent and the edge. To solve this problem, use every other square.

Shore Durometer Test Blocks

Part No:

Shore-A

Shore-D

RBB-94

RBC-63

RBR-30

Penetrator

Shore Durometer Type A Kit

Shore Durometer Type D Kit

RBB-94 Durometer

RBC-63 Durometer

RBR-30 Durometer

Rockwell Testing Accessories

ASTM E-18

ISO 6508

Part No:

P10100

P10100A

P10200

P10200A

P10300

P10301

P1040

P10400

P10401

P1045

P10450

P10501

P1050A

P1060

P1060A

P1061

P1070

P10700

P10700A

P10701

P1070A

P1071

P1072

P1073

P10800

P10801

P10802

P10803

P10804

P10806

P10807

P10808

P10809

P10810

P10811

P10812

P10813

P1110

P1120

Description

“C,A,D” Scale Grade B Pen

“C,A,D” Scale Grade A Regular

“N” Scale Grade B

“N” Scale Grade A Regular

“A” Scale Carbide

“A” Scale Carbide Indentron

“C” Dia. Pen-Versitron

“C” Scale Grade B Tapered Vers

“C” Scale Tapered Chinese

“N” Dia. Pen-Versitron

“N” Scale Grade B Tapered Vers

“C” Dia. Pen-Indentron

“C,A,D” Scale Grade A Indentro

“N” Scale Grade B Indentron

“N” Scale Grade A Indentron

“N” Scale Chinese

Combo C&N Regular

Combo C&N Indentron

Combo C&N Indentron Grade A

Combo C&N Versitron Scale Gr

Combo C&N Grade A

Combo C&N Versitron

Combo C&N Indentron

Combo C&N Scale Chinese

Mobile HRC Accredited

Mobile HRC Penetrator

Mobile HRN Penetrator

Mobile HRN Penetrator

Mobile C/N Combo Penetrator

Portable C Penetrator

Portable C Penetrator

Portable N Penetrator

Portable N Penetrator

Ames HRC Penetrator

Ames HRC Penetrator

Ames HRN Penetrator

Ames HRN Penetrator

Vickers Dia. Penetrator

Knoop Dia. Penetrator

Ball Penetrators

Part No:

P20100

P20101

P20102

P20103

P20200

P20201

P20202

P20203

P20204

P20205

P20206

P20207

P20208

P20300

P20301

P20400

P20401

P210104

P210105

P210106

P210107

P210108

P20150

P20250

P20350

P20450

Description

1/16” Ball Penetrator Standard

1/16” Ball Penetrator Indentron

1/16” Ball Penetrator Versitron

1/16” Mobile Penetrator

1/8” Ball Penetrator Unit

1/8” Ball Penetrator Indentron

1/8” Ball Penetrator Versitron

1/8” Ball Penetrator Mobile

1/8” Ball Penetrator Mobile

1/8” Ball Penetrator Portable

1/8” Ball Penetrator Portable

1/8” Ball Penetrator Ames

1/8” Ball Penetrator Ames

1/4” Ball Penetrator Standard

1/4” Ball Penetrator Indentron

1/2” Ball Penetrator Unit

1/2” Ball Penetrator Indentron

1/16” Mobile Ball Penetrator

1/16” Portable Ball Penetrator

1/16” Portable Ball Penetrator

1/16” Ames Ball Penetrator

1/16” Ames Ball Penetrator

1/16” Carbide Ball Accredited

1/8” Carbide Ball Accredited

1/4” Carbide Ball

1/2” Carbide Ball

Anvils

Part No:

A1010

A1011

A1012

A1014

A1020

A1025

A1030

A1040

A1050

A1055

A1060

A1080

A1090

A3020

Description

Pedestal Spot (1/4") Anvil

1" Spot Anvil:

Pedestal Spot (1/2") Anvil

Pedestal Spot (1") Anvil

1 1/2" Flat Anvil

1 1/4" Flat Anvil

2 1/2" Flat Anvil

Shallow "V" Anvil

Standard "V" Anvil

3 1/2" "V" Anvil

4" "V" Anvil

Diamond Spot Anvil

Cylindron Jr. Anvil

8" Testing Table

Brinell Testing Blocks and Accessories

ASTM E-10

ISO 6506

All of our Brinell Test Blocks come with accreditation to applicable standards. We adhere to a strict procedure for the calibration of these blocks, and the accuracy of the tester is maintained using a proving ring and load cell both traceable to N.I.S.T. The readings themselves are done using a stage micrometer also calibrated and traceable to N.I.S.T.

Test Conditions and Recommended Hardness Range

Brinell

Hardness

Scale

HBW 10/3000

HBW 10/1500

HBW 10/1000

HBW 10/500

HBW 10/250

HBW 10/125

HBW 10/100

HBW 5/750

HBW 5/250

HBW 5/125

HBW 5/62.5

HBW 5/31.25

HBW 5/25

HBW 2.5/187.5

HBW 2.5/62.5

HBW 2.5/31.25

HBW 2.5/15.625

HBW 2.5/7.8125

HBW 2.5/6.25

HBW 1/30

HBW 1/10

HBW 1/5

HBW 1/2.5

HBW 1/1.25

HBW 1/1

Ball Diameter

D mm

10

10

10

10

10

10

10

5

5

5

5

5

5

2.5

2.5

2.5

2.5

2.5

2.5

1

1

1

1

1

1

Force Diameter

RatioA

30

15

10

5

2.5

1.25

1

30

10

5

2.5

1.25

1

30

10

5

2.5

1.25

1

30

10

5

2.5

1.25

1

Nominal Value

of Test Force, F

N kgf

29420

14710

9807

4903

2452

1226

980.7

7355

2452

1226

612.9

306.5

245.2

1839

612.9

306.5

153.2

76.61

61.29

294.2

98.07

49.03

24.52

12.26

9.807

3000

1500

1000

500

250

125

100

750

250

125

62.5

31.25

25

187.5

62.5

31.25

15.625

7.8125

6.25

30

10

5

2.5

1.25

1

Recommended Hardness Range HBW

95.5 to 650

47.7 to 327

31.8 to 218

15.9 to 109

7.96 to 54.5

3.98 to 27.2

3.18 to 21.8

95.5 to 650

31.8 to 218

15.9 to 109

7.98 to 54.5

3.98 to 27.2

3.18 to 21.8

95.5 to 650

31.8 to 218

15.9 to 109

7.96 to 54.5

3.98 to 27.2

3.18 to 21.8

95.5 to 650

31.8 to 218

15.9 to 109

7.96 to 54.5

3.98 to 27.2

3.18 to 21.8

Note: Circle and gridded blocks available at additional cost. Dimensions for the most common blocks will be 6" x 2" x 3/4". The other dimensions are 6" x 41/2" x 3/4" or 2" x 2". Depends on ASTM E10-17 rules for dimensions. Call for prices and availability. Material used - steel, brass or aluminum depends on hardness.

Brinell Accessories

All Brinell scales to ASTM E-10 Table-3 available

Part No:

P3134

P3020

P3131

P3031

P3132

P3032

P3135

P3035

Description

10 mm Accredited Carbide Ball Indentor

10 mm Accredited Ball

5 mm Accredited Carbide Ball Indentor

5 mm Accredited Carbide Ball

2.5 mm Accredited Carbide Ball Indentor

2.5 mm Accredited Carbide Ball

1 mm Accredited Carbide Ball Indentor

1 mm Accredited Carbide Ball

Micro Hardness Test Blocks

ASTM E-92 - ISO 6507 & 4545

ASTM E-384 - ISO 6507

Our range of micro hardness test blocks exceed industry standards. All of our micro test blocks are mirror-polished and mounted to provide the best possible test surface.

Each mirror-polished Heavy Load Vickers test block has the same surface area provided by our Rockwell test blocks, so that you get the most test opportunities for your money.

Micro Hardness Test Blocks

Part No: Description Range

MV010 Vickers (1 gram to 1,000 gram) All Ranges

MV020 Heavy Load Vickers (1 Kg to 50 Kg) All Ranges

MK010 Knoop (1 gram to 1,000 gram) All Ranges

Note: When ordering please specify Knoop or Vickers, Load and the Hardness Range Number you require. On most Test Block Grids are available at additional cost.

Micro Hardness Accessories

Part No: Description

P1110 Vickers Diamond Penetrator*

* Vickers Indentor available for most of the different makes. Please specify the make of your hardness tester when ordering.

P1120 Knoop Diamond Penetrator*

* Knoop Indentor available for most of the different makes. Please specify the make of your

hardness tester when ordering.

Note: Dual calibration on the same block is available upon request.

Master Calibration Kits

Grade A

Our Master Calibration Kits are produced to provide our customers with the ultimate tool in Quality Control. Each kit contains a test block or blocks and the penetrator unit that was used to calibrate them. By matching specific blocks to a specific penetrator, a set relationship is established, and they can be eliminated as potential variables in the hardness test system. Should a problem arise, a master kit on hand allows you to quickly and accurately determine whether your hardness tester is the source.

Each block in our kits has been calibrated on a tester whose accuracy has been verified using N.I.S.T. traceable load and depth measuring devices. The individual test blocks are marked both with their own unique serial number. All of our kits come with their own polished wood case, and certificates covering to all the applicable standards.

Grade A Kits

HRB Scale with 1 1/16”

Part No: Description

K-B4020 3 Blocks

HRC Scale with C Diamond Penetrator

Part No: Description

K-C2020 3 Blocks

HRE Scale with 1/8” Carbide Ball Penetrator

Part No: Description

K-E2020 3 Blocks

HRN Scale with N Diamond and N Diamond Penetrator

Part No: Description

K-N2020 3 Blocks

Note: Grade B kits are available

For more information, or to place an order please E-mail our sales department at:

sales@dlellisco.com, fax us your Purchase Order at: 978.897.0844,

or call us toll-free at: 800.472.6962. Please specify your desired hardness range, when ordering.

Items Shipped UPS / FedEx or as directed.

Select Hardness Portables & Durometers Available

Q: How long do hardness blocks last?

A: Some blocks can last several years, though blocks can self-destruct in a short time from heavy use. Generally, soft blocks and high force testing can destroy a block in a matter of a month or so, especially if daily verification is required.

It is possible that a block become rendered useless due to changes in ASTM and ISO requirements. Such as the case of pre-NIST traceable HRC in 2000 and pre-E18-07a blocks calibrated without verified indenters.

Q: I asked for a 300 HV 0.5 micro-indentation test block and they sent me a 370 HV 0.5. I needed it to check a special part that I was manufacturing. Why can’t I get the exact value that I want?

A: Test blocks are used to verify the tester calibration, not your part. While it is desirable to get a block as close to your part hardness, it is not critical. Having said that, blocks are chosen from various heat treat lots to match the best possible. Also, different force and indenter combinations can affect the outcome of the block value you receive.

It is suggested that you look at the recommended hardness levels listed in ASTM and ISO documents.

Q: I am not sure what hardness scale to use. How can I find out?

A: A good place to start is part specifications within your company or your customer. Sometimes part specifications are listed with a common scale such as HRC, even though that scale can not be done on your part. This could be because the part is too thin or has a case hardness. ASTM and ISO charts give guidance on minimum thickness.

Be careful when using a tester by conversion or one that can electronically convert hardness scales. You can’t accredit conversions.

Find a distributor of David L. Ellis Co., Inc. products near your location.

Austria

Fa. Michael Neuhaus

Hormayrgasse 26 / 8

A – 1170 Wien

Tel: +43 6991 134 55 08

Fax: +43 1 481 04 96

E-Mail: office@neuhaus24.com

Web: www.neuhaus24.com

India

Metatech Industries

476 Narayan Peth, Cosmos Bank Building, 2nd Floor

Pune - 411 030 - INDIA

E-mail: sales@metatechind.com | consumables@metatechind.com

Website: www.metatechind.com

Tel: +91 – 20 – 2445 0312 / 2445 0530

Vietnam

QT Instruments (S) Pte Ltd

192 Pandan Loop, #06-20

Pantech Industrial Complex SINGAPORE 128381

Ask for: Dixon Ng

E-mail: sales@qt.com.sg

Tel: +65 6303 9833

Fax: +65 6778 2578

France

Cap-Mesure (La Rochelle)

Réseau commercial WIKA

Dpt. : Moyens d’Etalonnage & Capteurs

Distributeur France Blocs de Dureté D.L.E.

Bruno QUETEL

Tél. : +33 (0)5 46 35 41 72

Mob. : +33 (0)6 33 01 88 60

E-mail: quetel-bruno.capmesure@orange.fr

India

Sastha Scientific Agencies

314, 8th E Main, 4th Cross, Kalyan Nagar, HRBR I Block,

Bangalore - 560 043 - INDIA

Website: www.sasthascientific.com

TeleFax: 0091-80-25424670 / Hand Phone: 9845192860

Australia

Australian Calibration Services

126 Oxford Street,

Collingwood, Victoria 3066 - AUSTRALIA

Ask for: Mr Tim Kennon

E-mail: timkennon@auscal.com.au

Tel: +61 3 9417 5688

Fax: +61 3 9417 1578

Italy

La Marca

E-mail: g.lamarca@lamarcagroup.it

Ask for: Giovanni La Marca

Tel: +39-081.8411555

Fax: +39-081.8411553

The Netherlands

VEM Metallurgie bv

De Liesbosch 8E

3439 LC Nieuwegein

E-mail: info@vem-metallurgie.nl

Tel: +31 (0)30 6351001

Fax: +31 (0)30 6352683

United Kingdom

VEM Metallurgie bv

De Liesbosch 8E

3439 LC Nieuwegein

E-mail: info@vem-metallurgie.nl

Tel: +31 (0)30 6351001

Fax: +31 (0)30 6352683

China

Kingindent Test Instruments Co., Ltd.

Yong tai zhong lu, No.25,

Yong tai chuang xin yuan, B-138

Hai Dian District, P.C.100192

Beijing, P.R. CHINA

Ask for: Ma Wei

E-mail: service@kingindent.com

Website: http://www.kingindent.com

Tel: +86 10 62915875

Fax: +86 10 64772069

India

Bhartiya Enterprises

Plot No. 254 Sector-24

Faridabad, Haryana 121005 - INDIA

Ask for: Kapil Vashist

E-mail: bhartiya@airtelbroadband.in

Tel: +91 9810 088 217

Indonesia

Quantum Technologies Global Pte Ltd.

Blk 3007 Ubi Road 1

Unit No. #04-454

Singapore 408701

Ask for: Wina Lie

E-mail: sales-sg@quantumsg.com

Tel: +65 9009 1267

Fax: +65 6777 7169

Malaysia

Quantarad Technologies Sdn Bhd

No.49 Jalan Kiara SD11/5

Bandar Sri Damansara

52200 Kuala Lumpur - MALAYSIA

Ask for: Steve Koh

E-mail:steve.koh@quantumsg.com

Tel: +60 167227347

Fax: +603 7831 6279

Malaysia

MSP Metrology

10, Jalan Gemilang 9

Taman Perindustrian Cemerlang

81800 Ulu Tiram, Johor, Malaysia

E-mail: nicole@mspmetrology.com

Website: https://mspmetrology.com

Tel: +607 8626772

Singapore

Quantum Technologies Global Pte Ltd

Blk 3007 Ubi Road 1

Unit No. #04-454

Singapore 408701

Ask for: Wina Lie

E-mail: sales: sg@quantumsg.com

Tel: +65 9009 1267

Fax: +65 6777 7169

Taiwan

Sanpany Instruments Co., Ltd.

Tainan Branch 162

Chung Hsueh Rd.

Tainan 701, TAIWAN R.O.C.

Website: http://www.sanpany.com.tw

E-mail: lhm@sanpany.com.tw

Tel: 06-3351601

Fax: 06-3351602

North America

National Calibration

2380 Wyecroft Road

Unit 11 Oakville, ON L6L 6W1 - CANADA

Ask for: Doug Fox

E-mail: info@nationalcalibration.ca

Tel: (905) 825-3329

Fax: (905) 825-3033

Central America

SCM Metrología y Laboratorios S.A.

20109 Del Cruce Aeropuerto 2 km Carretera a Heredia

Rio Segundo Alajuela - Costa Rica

Ask for: Fernando Chacón Madrigal

E-mail: fchacon@scmmetrologia.com

Website: http://www.scmmetrologia.com

Tel: (506) 2431-5252

Fax: (506) 2432-4180

South America

RIO GRANDE DO SUL

MITEC Instrumentos Industriais Ltda.

Rua Antoninho D. Campagnollo, 33

Bairro Sanvitto, Esquina com Perimetral Sul

Caxias do Sul - RS, 95012-230 - BRAZIL

E-mail: mitec@mitec.com.br

Website: http://www.mitec.com.br

Tel: (54) 3225-3211

Fax: (54) 3225-3711

South America

SÃO PAULO

Importecnica

Av. Jamaris, 505

Moema - SP, 04078-001 - BRAZIL

Ask for: Lino

E-mail: lino@importecnica.com.br

Website: http://www.importecnica.com.br

Tel: (11) 5052-5344

Fax: (11) 5052-7051